Txhua tus tswvcuab los ntawm peb cov neeg ua haujlwm loj tau txais txiaj ntsig zoo rau cov neeg siv khoom xav tau thiab koom haum kev sib txuas lus rau High definition Tuam Tshoj Nkoj Moulds E-Glass Fiberglass Assembled Roving SMC, Zoo siab txais tos koj cov lus nug, lub tuam txhab zoo tshaj plaws yuav muab tag nrho lub siab.

Txhua tus tswv cuab los ntawm peb cov neeg ua haujlwm tau txais txiaj ntsig loj ua rau muaj txiaj ntsig rau cov neeg siv khoom xav tau thiab koom haum sib txuas lus rauNkoj Moulds E-iav Fiberglass Roving SMC, Tuam Tshoj Fiberglass SMC Roving, Peb lub tuam txhab muaj ntau yam los ntawm kev muag khoom ua ntej mus rau tom qab muag kev pab cuam, los ntawm cov khoom tsim los mus soj ntsuam kev siv cov kev tu, raws li lub zog technical, superior khoom kev ua tau zoo, tus nqi tsim nyog thiab kev pabcuam zoo meej, peb yuav txuas ntxiv txhim kho, xa cov khoom zoo thiab cov kev pabcuam, thiab txhawb kev koom tes nrog peb cov neeg siv khoom, kev txhim kho thiab tsim lub neej yav tom ntej zoo dua.

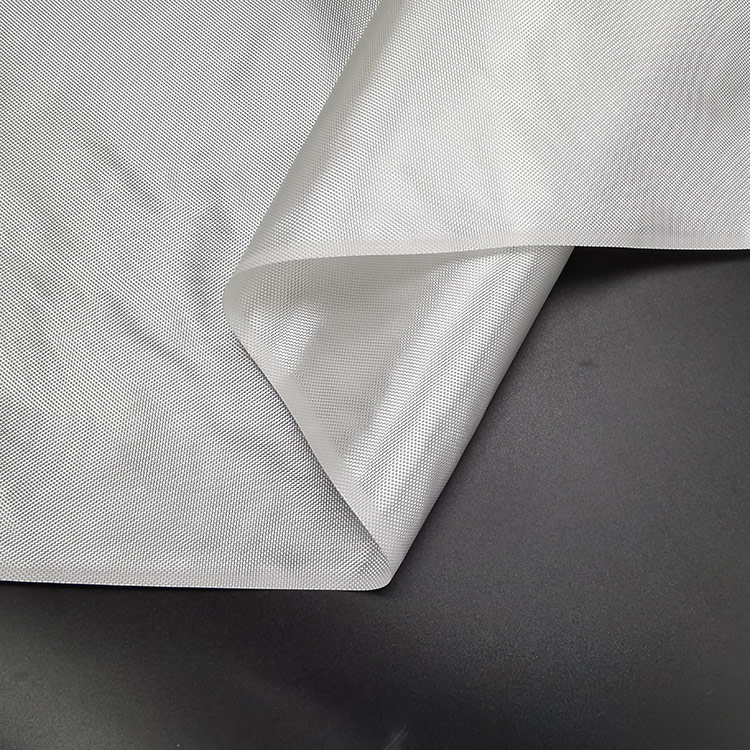

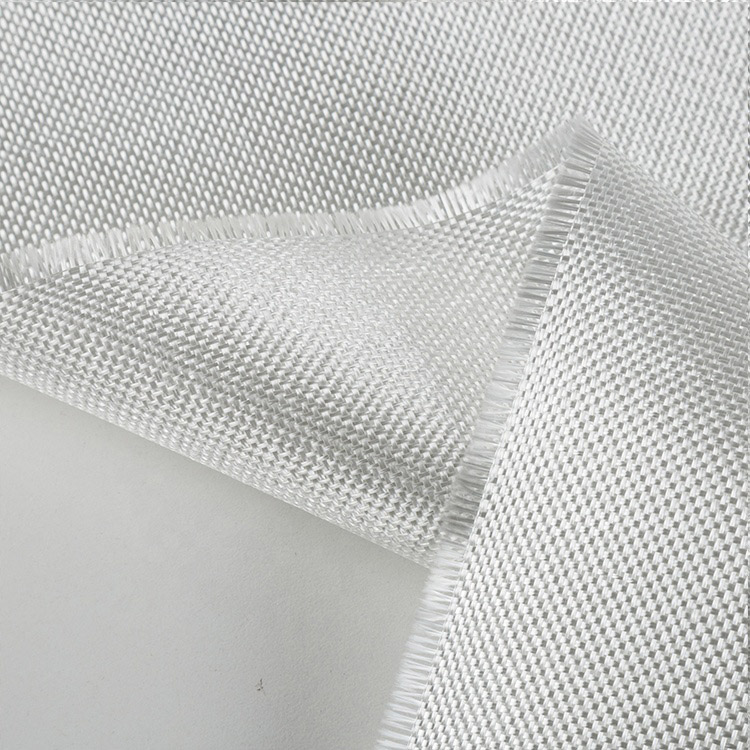

Cov khoom no yog Assembled Roving rau cov qauv kev ua haujlwm siab SMC.Cov xov paj saum npoo yog coated nrog silane composite sizing, uas yog haum rau ntxiv dag zog rau unsaturated polyester resins thiab vinyl resins.

Cov khoom no yog Assembled Roving ua los ntawm alkali-dawb iav hlau kos duab.Nws txais kev sib cais tshwj xeeb thiab kev sib cais.Hom 448 muaj qhov nrawm nrawm nrawm hauv styrene thiab tsis tshua muaj peev xwm adsorption.Nws tseem tuaj yeem nkag mus rau hauv cov ntsiab lus ntawm cov iav fiber ntau.Nrog cov khoom ntws zoo heev hauv cov resin, Model 456 yog tsim rau siab viscosity paste, siab tshuab ceev, tuab daim ntawv ntau lawm.

Cov khoom siv yog siv hauv SMC cov khoom ntawm cov txheej txheem kub molding, xws li cov khoom siv hauv chav dej uas xav tau cov khoom zoo thiab cov xim.Ua cov ntawv qis qis thiab tseem tuaj yeem siv rau cov ntawv qis qis.Cov khoom lag luam yog: ntau yam pib qhov chaw, qhov rooj tawv nqaij, lub tank dej, cov khoom siv hluav taws xob, thiab lwm yam. Kev tsim cov khoom siv tsheb, tsheb chassis, hoods, thiab lwm yam.

Specification

| Qauv | Hom iav | Sizing hom | Hom filament txoj kab uas hla (um) | Hom linear ceev (tex) |

| Qauv: ER-410J | E | Silane | 14 | 4800 ib |

| SIB-440 | 14/15/16 | 2400/4400/4800 |

| Qauv: ER-440A | 13 | 2400/4800 Nws |

| Qauv: ER-442K | 14 | 2400/4800 Nws |

| TIAB SA-448 | 13 | 4400 ib |

| TIAB SA-456 | 15 / 16 ib | 2400/4400/4800 |

| TIAB SA-458 | 14 | 4500/4800 Nws |

Technical Parameters

| Qauv | Linear density variation (%) | Cov dej noo (%) | Qhov loj me (%) | Kev nruj (mm) |

| Qauv: ER-410J | ± 4 | ≤ 0.07 | 1.25 ± 0.15 | 150 ± 20 |

| SIB-440 | 1.25 ± 0.15 | 160 ± 20 (14um ~ 15um)

170 ± 20 (16um; 440 (80)) |

| Qauv: ER-440A | 1.15 ± 0.15 | 145 ± 20 |

| Qauv: ER-442K | 1.25 ± 0.15 | 150 ± 20 |

| TIAB SA-448 | 1.90 ± 0.20 | 160 ± 20 |

| TIAB SA-456 | 2.00 ± 0.20 | 170 ± 20 |

| TIAB SA-458 | 2.00 ± 0.20 | 160 ± 20 |

Cov lus qhia

◎ Lub sijhawm siv zoo tshaj plaws ntawm cov khoom yog 12 lub hlis, thov khaws cia rau hauv cov ntim thawj zaug ua ntej siv los xyuas kom meej cov khoom zoo.

◎ Thaum siv cov khoom no, thov ua tib zoo saib xyuas kev tiv thaiv rov los ntawm kev khawb lossis puas, uas yuav cuam tshuam rau kev siv.

◎ Thov xyuam xim rau qhov cuam tshuam ntawm ambient kub thiab av noo ntawm cov khoom.Txhawm rau ua tiav cov khoom lag luam zoo tshaj plaws, qhov ntsuas kub thiab av noo tuaj yeem hloov kho kom tsim nyog.

◎ Txhawm rau txhim kho cov txheej txheem zoo, thov tswj cov cuab yeej ua haujlwm tsis tu ncua txhawm rau txhim kho kev tsim khoom.

Ntim

Cov khoom yog ntim rau hauv ib lub tais ntoo kom tsis muaj menyuam, nrog rau daim duab los qhia rau txheej sab hauv, lub pob rov yog npog nrog cov yas shrink zaj duab xis, thiab txheej txheej sab nraud yog ntim nrog zaj duab xis ncab.

Cia

Raws li ib txwm muaj, qhov chaw cia khoom zoo tshaj plaws rau cov khoom siv iav fiber ntau yog txias thiab qhuav, qhov kub thiab txias yog -10 ℃ ~ 35 ℃, thiab cov av noo yog ≤80%.Lub stacking ntawm fiberglass cov khoom yuav tsum tsis txhob ntau tshaj peb txheej, thov ua nws smoothly thiab raug thaum lub sij hawm stacking.

Txhua tus tswvcuab los ntawm peb cov neeg ua haujlwm loj tau txais txiaj ntsig zoo rau cov neeg siv khoom xav tau thiab koom haum kev sib txuas lus rau High definition Tuam Tshoj Nkoj Moulds E-Glass Fiberglass Assembled Roving SMC, Zoo siab txais tos koj cov lus nug, lub tuam txhab zoo tshaj plaws yuav muab tag nrho lub siab.

Siab txhaisTuam Tshoj Fiberglass SMC Roving, Nkoj Moulds E-iav Fiberglass Roving SMC, Peb lub tuam txhab muaj ntau yam los ntawm kev muag khoom ua ntej mus rau tom qab muag kev pab cuam, los ntawm cov khoom tsim los mus soj ntsuam kev siv cov kev tu, raws li lub zog technical, superior khoom kev ua tau zoo, tus nqi tsim nyog thiab kev pabcuam zoo meej, peb yuav txuas ntxiv txhim kho, xa cov khoom zoo thiab cov kev pabcuam, thiab txhawb kev koom tes nrog peb cov neeg siv khoom, kev txhim kho thiab tsim lub neej yav tom ntej zoo dua.

Yav dhau los: Tshiab xa rau Tuam Tshoj 300tex-2400tex Fiberglass Roving / Direct Roving iav Fiber Yran rau Weaving Tom ntej: Tuam Tshoj Plain Weave E-iav Fiberglass Woven Roving 600GSM