Cov khoom siv raw ntawm cov ntaub ntawv sib xyaw muaj xws li resin, fiber ntau thiab cov khoom tseem ceeb, thiab lwm yam.Muaj ntau txoj kev xaiv, thiab txhua yam khoom muaj nws lub zog tshwj xeeb, nruj, toughness thiab thermal stability, thiab nws cov nqi thiab cov zis kuj txawv.

Txawm li cas los xij, cov khoom siv sib xyaw ua ke tag nrho, nws qhov kev ua tau zoo kawg nkaus tsis yog tsuas yog cuam tshuam nrog cov resin matrix thiab fibers (thiab cov khoom siv tseem ceeb hauv cov qauv sandwich), tab sis kuj tseem cuam tshuam nrog cov qauv tsim thiab kev tsim cov khoom siv hauv cov qauv. .

Kab lus no yuav qhia txog cov txheej txheem kev tsim khoom siv feem ntau, qhov tseem ceeb cuam tshuam ntawm txhua txoj kev thiab yuav ua li cas xaiv cov khoom siv raw rau cov txheej txheem sib txawv.

Txoj kev piav qhia:Cov txheej txheem molding nyob rau hauv uas cov chopped fiber reinforced cov khoom thiab cov resin system yog txau rau hauv pwm tib lub sij hawm, thiab ces kho nyob rau hauv ib txwm siab los tsim ib tug thermosetting composite khoom.

xaiv cov khoom siv:

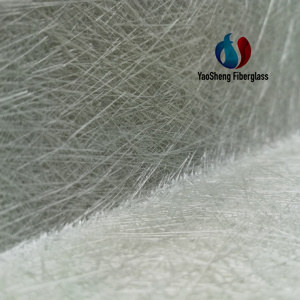

Resin: feem ntau yog polyester

Fiber: coarse iav fiber ntau xov paj

Cov khoom siv tseem ceeb: Tsis yog, yuav tsum tau ua ke nrog laminates nyias

Lub ntsiab kom zoo dua:

1) craftsmanship muaj keeb kwm ntev

2) Tus nqi qis, ceev fiber ntau thiab resin tso

3) Tus nqi pwm tsawg

Lub ntsiab tsis zoo:

1) Lub laminated board yog ib qho yooj yim los tsim ib qho chaw resin enriched, thiab qhov hnyav yog qhov siab.

2) Tsuas yog chopped fibers tuaj yeem siv tau, uas txwv tsis pub cov khoom siv ntawm laminates hnyav

3) Txhawm rau txhawm rau txhawm rau txhawm rau txau, cov viscosity resin yuav tsum qis txaus kom poob cov khoom siv hluav taws xob thiab thermal ntawm cov khoom sib xyaw.

4) Cov ntsiab lus styrene siab nyob rau hauv cov tshuaj tsuag resin txhais tau hais tias muaj kev phom sij ntau dua rau cov neeg ua haujlwm, thiab cov viscosity tsawg txhais tau hais tias cov resin yooj yim nkag mus rau hauv cov khaub ncaws ua haujlwm ntawm cov neeg ua haujlwm thiab ncaj qha rau ntawm daim tawv nqaij.

5) Lub concentration ntawm styrene volatilized nyob rau hauv cov huab cua yog nyuaj rau ua tau raws li txoj cai

daim ntawv thov raug:

Tej yam yooj yim fencing, uas tsis muaj loads structural panels xws li convertible tsheb lub cev, tsheb fairings, bathtubs thiab me me nkoj

Kev piav qhia ntawm txoj kev:Manually impregnate cov fibers nrog resin.Cov fibers tuaj yeem txhawb nqa los ntawm kev xaws, braiding, xaws los yog khi.Tes nteg-up feem ntau yog ua nrog cov chais lossis txhuam, thiab tom qab ntawd cov resin yog nyem nrog cov roj hmab cov menyuam kom nkag mus rau cov fibers.Cov laminates tau kho raws li qhov qub.

xaiv cov khoom siv:

Resin: tsis tas yuav tsum tau, epoxy, polyester, polyvinyl ester, phenolic resin tau txais

Fiber: Tsis muaj qhov yuav tsum tau ua, tab sis aramid fiber ntau nrog lub hauv paus hnyav dua yog qhov nyuaj rau kev nkag mus los ntawm tes nteg

Cov khoom siv tseem ceeb: tsis xav tau

Lub ntsiab kom zoo dua:

1) craftsmanship muaj keeb kwm ntev

2) Yooj yim kawm

3) Yog tias chav tsev kub curing resin siv, tus nqi pwm yog tsawg

4) Kev xaiv ntau ntawm cov ntaub ntawv thiab cov neeg muag khoom

5) Cov ntsiab lus fiber ntau, cov fibers siv tau ntev dua li cov txheej txheem txau

Lub ntsiab tsis zoo:

1) Resin mixing, resin cov ntsiab lus thiab qhov zoo ntawm laminates yog ze ze rau kev ua haujlwm ntawm cov neeg ua haujlwm, nws yog qhov nyuaj kom tau txais laminates nrog cov ntsiab lus qis thiab cov porosity tsawg.

2) Kev noj qab haus huv thiab kev nyab xeeb ntawm cov resin.Qhov qis dua qhov hnyav molecular ntawm tes nteg-up resin, qhov loj dua qhov muaj feem cuam tshuam txog kev noj qab haus huv.Qhov qis dua qhov viscosity, nws yooj yim dua rau cov resin nkag mus rau hauv cov khaub ncaws ua haujlwm ntawm cov neeg ua haujlwm thiab ncaj qha rau ntawm daim tawv nqaij.

3) Yog tias cov khoom siv cua tsis zoo tsis tau teeb tsa, qhov concentration ntawm styrene volatilized los ntawm polyester thiab polyvinyl ester rau hauv cov huab cua yog qhov nyuaj kom ua tau raws li txoj cai.

4) Lub viscosity ntawm tes lay-up resin yuav tsum qis heev, yog li cov ntsiab lus ntawm styrene lossis lwm cov kuab tshuaj yuav tsum siab, yog li poob cov khoom siv hluav taws xob / thermal ntawm cov khoom sib xyaw.

Tej kev siv:txheem cua turbine hniav, loj-tsim nkoj, architectural qauv

Txoj kev piav qhia:Cov txheej txheem ntawm lub hnab nqus tsev yog qhov txuas ntxiv ntawm cov txheej txheem saum toj no-hais tes nteg, uas yog, txheej txheej ntawm cov yas zaj duab xis yog kaw rau ntawm pwm los nqus cov tes-ntug laminate, thiab cov cua kub yog siv rau laminate kom ua tiav. cov nyhuv ntawm cov pa tawm thiab compaction.Txhawm rau txhim kho qhov zoo ntawm cov khoom sib xyaw.

xaiv cov khoom siv:

Resin: feem ntau epoxy thiab phenolic resin, polyester thiab polyvinyl ester tsis haum vim lawv muaj styrene, uas volatilizes rau hauv lub tshuab nqus tsev twj.

Fiber: Tsis muaj qhov yuav tsum tau ua, txawm tias fibers nrog lub hauv paus hnyav tuaj yeem ntub dej hauv qhov siab

Cov khoom siv tseem ceeb: tsis xav tau

Lub ntsiab kom zoo dua:

1) tuaj yeem ua tiav cov ntsiab lus fiber ntau dua li txheej txheem txheej txheem tes

2) Lub porosity qis dua tus txheej txheem tes nteg

3) Nyob rau hauv cov xwm txheej ntawm qhov tsis zoo siab, tag nrho cov dej ntws ntawm cov resin txhim kho cov qib ntawm ntub dej ntawm cov fibers.Ntawm chav kawm, ib feem ntawm cov resin yuav absorbed los ntawm lub tshuab nqus tsev consumables

4) Kev Noj Qab Haus Huv thiab Kev Nyab Xeeb: Cov txheej txheem ntawm lub hnab nqus tsev tuaj yeem txo qhov kev tso tawm ntawm cov volatiles thaum kho

Lub ntsiab tsis zoo:

1) Cov txheej txheem ntxiv nce tus nqi ntawm kev ua haujlwm thiab cov khoom siv lub tshuab nqus tsev pov tseg

2) Cov kev xav tau siab dua rau cov neeg ua haujlwm

3) Kev tswj cov khoom sib xyaw thiab cov ntsiab lus ntawm cov resin feem ntau yog nyob ntawm tus neeg ua haujlwm tau zoo

4) Txawm hais tias lub hnab nqus tsev txo qhov tso tawm ntawm cov volatiles, kev noj qab haus huv kev hem thawj rau tus neeg teb xov tooj tseem siab dua li cov txheej txheem infusion lossis prepreg.

Tej kev siv:loj-teev, ib-lub sij hawm txwv-duab yachts, sib tw tsheb qhov chaw, kev sib txuas ntawm cov khoom tseem ceeb hauv shipbuilding

Deyang Yaosheng Composite Material Co., Ltd.yog ib lub tuam txhab kev lag luam uas tsim ntau yam iav fiber ntau cov khoom.Lub tuam txhab tsuas yog tsim Fiberglass roving, iav fiber ntau tws strand lev, iav fiber ntau ntaub / roving ntaub / marine daim ntaub, thiab lwm yam. Thov koj xav tiv tauj peb.

Xov tooj: +86 15283895376

Whatsapp: +86 15283895376

Email: yaoshengfiberglass@gmail.com

Kev piav qhia ntawm txoj kev:Cov txheej txheem winding yog siv los tsim cov hollow, puag ncig lossis oval yam xws li cov kav dej thiab cov tso tsheb hlau luam.Tom qab cov khoom siv fiber ntau yog impregnated nrog cov resin, nws raug mob ntawm mandrel nyob rau hauv ntau cov lus qhia, thiab cov txheej txheem yog tswj los ntawm lub tshuab winding thiab mandrel ceev.

xaiv cov khoom siv:

Resin: tsis tas yuav tsum muaj, xws li epoxy, polyester, polyvinyl ester thiab phenolic resin, thiab lwm yam.

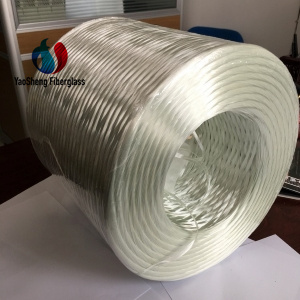

Fiber: tsis tas yuav tsum tau, ncaj qha siv cov fiber ntau ntawm cov creel, tsis tas yuav xaws los yog xaws rau hauv cov ntaub fiber ntau

Cov khoom siv tseem ceeb: tsis muaj qhov yuav tsum tau ua, tab sis daim tawv nqaij feem ntau yog ib txheej ntawm cov khoom sib xyaw

Lub ntsiab kom zoo dua:

1) Kev tsim khoom ceev ceev, thiab nws yog ib qho kev lag luam thiab tsim nyog txheej txheej

2) Cov ntsiab lus resin tuaj yeem tswj tau los ntawm kev ntsuas tus nqi ntawm cov khoom nqa los ntawm cov khoom siv fiber ntau dhau los ntawm lub tank resin

3) Tsawg tus nqi fiber ntau, tsis muaj txheej txheem nruab nrab

4) Cov txheej txheem kev ua tau zoo yog qhov zoo heev, vim tias cov kab ntawv fiber ntau tuaj yeem muab tso rau hauv ntau yam kev coj ua.

Lub ntsiab tsis zoo:

1) Cov txheej txheem no tsuas yog siv rau cov vaj huam sib luag hollow

2) Cov fibers tsis yooj yim rau kev teeb tsa raws li axial kev taw qhia ntawm cov khoom

3) Tus nqi ntawm mandrel txiv neej pwm rau cov qauv loj yog qhov siab

4) Sab nrauv ntawm cov qauv tsis yog pwm nto, yog li qhov zoo nkauj tsis zoo

5) Thaum siv cov viscosity tsawg, kev saib xyuas yuav tsum tau them rau cov tshuaj ua haujlwm thiab kev noj qab haus huv thiab kev nyab xeeb

Tej kev siv:chemical cia tso tsheb hlau luam thiab xa cov kav dej, lub tog raj kheej, cov twj tua hluav taws ua pa

Txoj kev piav qhia:Cov khoom siv fiber ntau rub tawm los ntawm cov creel yog dipped thiab dhau los ntawm cov cua sov phaj, thiab cov resin yog infiltrated rau hauv fiber ntau ntawm lub phaj cua sov, thiab cov ntsiab lus ntawm cov resin yog tswj, thiab thaum kawg cov khoom yog kho rau hauv cov duab yuav tsum tau;Cov khoom zoo li no kho kho yog Mechanically txiav rau ntau qhov ntev.Fibers tseem tuaj yeem nkag mus rau lub phaj kub hauv cov lus qhia uas tsis yog 0 degrees.

Pultrusion yog cov txheej txheem tsim khoom tas mus li, thiab ntu ntu ntawm cov khoom feem ntau muaj qhov ruaj khov, tso cai hloov me ntsis.Kho cov khoom ntub dej ua ntej dhau los ntawm lub phaj kub thiab kis mus rau hauv pwm kom kho tam sim.Txawm hais tias cov txheej txheem no muaj kev tsis zoo txuas ntxiv, nws tuaj yeem hloov pauv cov duab sib luag.

xaiv cov khoom siv:

Resin: feem ntau epoxy, polyester, polyvinyl ester thiab phenolic resin, thiab lwm yam.

Fiber: tsis xav tau

Cov khoom siv tseem ceeb: tsis siv ntau

Lub ntsiab kom zoo dua:

1) Kev tsim khoom nrawm nrawm, thiab nws yog ib qho kev lag luam thiab tsim nyog rau cov ntaub ntawv ua ntej ntub thiab kho

2) Precise tswj cov ntsiab lus resin

3) Tsawg tus nqi fiber ntau, tsis muaj txheej txheem nruab nrab

4) Kev ua haujlwm zoo heev, vim tias cov pob khoom fiber ntau tau teeb tsa hauv txoj kab ncaj nraim thiab cov fiber ntau feem ntau

5) Qhov chaw fiber ntau infiltration tuaj yeem raug kaw kom txo tau qhov tso tawm ntawm cov volatiles

Lub ntsiab tsis zoo:

1) Cov txheej txheem no txwv txoj kev hla ntu

2) Tus nqi ntawm cov phaj cua sov yog qhov siab

Tej kev siv:Beams thiab trusses rau cov qauv tsev, txuas hniav, ntaiv thiab laj kab

6. Resin Hloov Moulding (RTM)

Txoj kev piav qhia:Tso cov fibers qhuav hauv cov pwm qis, siv lub zog ua ntej kom cov fibers haum cov pwm kom ntau li ntau tau, thiab khi lawv;Tom qab ntawd, kho cov pwm sab saud ntawm cov pwm qis kom tsim cov kab noj hniav, thiab tom qab ntawd txhaj cov resin rau hauv pwm kab noj hniav.

Vacuum assisted resin txhaj tshuaj thiab infiltration ntawm fibers feem ntau yog siv, uas yog lub tshuab nqus tsev pab resin infusion txheej txheem (VARI).Thaum fiber ntau infiltration tiav lawm, cov resin introduction valve raug kaw thiab cov composite yog kho.Resin txhaj thiab kho tuaj yeem ua tiav ntawm chav tsev kub lossis hauv qab cua sov.

xaiv cov khoom siv:

Resin: feem ntau epoxy, polyester, polyvinyl ester thiab phenolic resin, bismaleimide resin tuaj yeem siv rau qhov kub thiab txias

Fiber: Tsis xav tau.Stitched fibers yog tsim nyog rau cov txheej txheem no vim hais tias cov fiber ntau bundles yooj yooj yim hloov resin;muaj tshwj xeeb tsim fibers los pab txhawb resin ntws

Cov khoom siv tseem ceeb: Honeycomb ua npuas ncauj tsis haum, vim hais tias cov honeycomb hlwb yuav ntim nrog cov resin, thiab lub siab yuav ua rau cov npuas dej tawg.

Lub ntsiab kom zoo dua:

1) High fiber ntau feem thiab porosity tsawg

2) Txij li cov resin raug kaw tag, nws muaj kev noj qab haus huv thiab nyab xeeb, thiab qhov chaw ua haujlwm yog huv thiab huv.

3) Txo kev siv zog ua haujlwm

4) Sab sauv thiab sab qis ntawm cov txheej txheem yog pwm, uas yooj yim rau kev kho tom qab

Lub ntsiab tsis zoo:

1) Cov pwm siv ua ke yog kim, thiab thiaj li yuav tiv taus siab dua, nws hnyav thiab kuj cumbersome

2) Txwv rau kev tsim khoom me me

3) Cov cheeb tsam uas tsis yog ntub dej tuaj yeem tshwm sim, ua rau muaj cov khoom seem ntau

Tej kev siv:me me thiab complex chaw shuttle thiab nws pib qhov chaw, tsheb ciav hlau rooj

7. Lwm cov txheej txheem perfusion - SCRIMP, RIFT, VARTM, thiab lwm yam.

Method Description:Tso cov fibers qhuav zoo ib yam li cov txheej txheem RTM, tom qab ntawd nteg cov ntaub tso tawm thiab cov dej ntws tawm.Tom qab layup tiav lawm, nws yog kiag li kaw nrog ib lub hnab nqus tsev vacuum, thiab thaum lub nqus tsev vacuum ncav cuag ib tug tej yam yuav tsum tau, resin yog nkag mus rau hauv tag nrho cov layup qauv.Kev faib cov resin nyob rau hauv lub laminate yog ua tiav los ntawm kev coj cov resin ntws los ntawm kev qhia net, thiab thaum kawg cov fibers qhuav yog infiltrated los ntawm sab saum toj mus rau hauv qab.

xaiv cov khoom siv:

Resin: feem ntau epoxy, polyester, polyvinyl ester resin

Fiber: Txhua hom fiber ntau.Stitched fibers yog qhov zoo dua rau cov txheej txheem no raws li cov khoom siv fiber ntau nrawm nrawm hloov pauv hloov pauv

Cov khoom siv tseem ceeb: honeycomb ua npuas ncauj tsis siv tau

Lub ntsiab kom zoo dua:

1) Ib yam li RTM txheej txheem, tab sis tsuas yog ib sab yog pwm nto

2) Ib sab ntawm cov pwm yog lub hnab nqus tsev, uas txuag tau tus nqi ntawm pwm thiab txo qhov yuav tsum tau rau pwm kom tiv taus siab.

3) Cov txheej txheem loj tuaj yeem muaj cov khoom siv fiber ntau thiab cov porosity tsawg

4) Cov txheej txheem tes txheej txheem pwm tuaj yeem siv rau cov txheej txheem no tom qab hloov kho

5) Cov qauv sandwich tuaj yeem ua pwm rau ib zaug

Lub ntsiab tsis zoo:

1) Rau cov qauv loj, cov txheej txheem yog qhov nyuaj, thiab kev kho tsis tuaj yeem zam

2) Lub viscosity ntawm cov resin yuav tsum tsawg heev, uas kuj txo cov neeg kho tshuab zog

3) Cov cheeb tsam uas tsis yog ntub dej tuaj yeem tshwm sim, ua rau muaj cov khoom seem ntau

Tej kev siv:Kev sim tsim cov nkoj me me, lub cev vaj huam sib luag rau tsheb ciav hlau thiab tsheb thauj khoom, cua turbine hniav

8. Prepreg - txheej txheem autoclave

Txoj kev piav qhia:Cov ntaub fiber ntau los yog fiber ntau yog pre-impregnated los ntawm cov chaw tsim khoom siv nrog cov resin uas muaj cov catalyst, thiab cov txheej txheem tsim khoom yog kev kub siab thiab kev kub siab los yog cov txheej txheem hnyav.Lub catalyst yog latent nyob rau hauv chav tsev kub, muab cov khoom txee lub neej ntawm lub lis piam los yog hli nyob rau hauv chav tsev kub;tub yees tuaj yeem txuas nws lub neej txee.

Lub prepreg tuaj yeem yog tes lossis tshuab nteg rau saum npoo ntawm pwm, tom qab ntawd npog hauv lub hnab nqus tsev thiab ua kom sov rau 120-180 ° C.Tom qab cua sov cov resin tuaj yeem ntws rov qab thiab nws thiaj li kho tau.Ib qho autoclave tuaj yeem siv los siv lub siab ntxiv rau cov khoom siv, feem ntau txog li 5 cua.

xaiv cov khoom siv:

Resin: feem ntau epoxy, polyester, phenolic resin, kub resistant resin xws li polyimide, cyanate ester thiab bismaleimide kuj siv tau.

Fiber: Tsis xav tau.Fiber bundle lossis fiber ntau tuaj yeem siv tau

Cov khoom siv tseem ceeb: tsis tas yuav tsum tau ua, tab sis cov npuas dej yuav tsum tau tiv taus qhov kub thiab txias

Lub ntsiab kom zoo dua:

1) Qhov piv ntawm resin rau curing tus neeg saib xyuas thiab cov ntsiab lus ntawm cov khoom siv tau raug teeb tsa los ntawm tus neeg muag khoom, nws yooj yim heev kom tau txais laminates nrog cov ntsiab lus fiber ntau thiab tsis tshua muaj porosity.

2) Cov khoom siv muaj cov yam ntxwv zoo rau kev noj qab haus huv thiab kev nyab xeeb, thiab qhov chaw ua haujlwm huv si, muaj peev xwm txuag tau automation thiab nqi zog.

3) Tus nqi ntawm unidirectional cov ntaub ntawv fibers yog tsawg, thiab tsis muaj cov txheej txheem nruab nrab yuav tsum tau weave fibers rau hauv daim ntaub

4) Cov txheej txheem tsim khoom yuav tsum tau cob nrog siab viscosity thiab zoo wettability, nrog rau kev ua kom zoo dua qub thiab thermal zog

5) Kev ncua sijhawm ua haujlwm ntawm chav tsev kub txhais tau hais tias kev txhim kho cov txheej txheem thiab kev teeb tsa ntawm cov duab nyuaj kuj yooj yim ua tiav

6) Muaj peev xwm txuag tau hauv automation thiab nqi zog

Lub ntsiab tsis zoo:

1) Tus nqi ntawm cov ntaub ntawv nce ntxiv, tab sis nws tsis tuaj yeem zam tau kom ua tau raws li daim ntawv thov

2) Ib qho autoclave yuav tsum ua kom tiav qhov kho, uas muaj tus nqi siab, lub sijhawm ua haujlwm ntev thiab kev txwv loj

3) Cov pwm yuav tsum tiv taus cov txheej txheem kub, thiab cov khoom tseem ceeb muaj tib yam kev xav tau

4) Rau cov khoom tuab, lub tshuab nqus tsev ua ntej yuav tsum tau muab tso rau hauv prepregs kom tshem tawm cov cua npuas interlayer

Tej kev siv:qhov chaw shuttle qhov chaw (xws li tis thiab tails), F1 sib tw tsheb

9. Prepreg – cov txheej txheem tsis-autoclave

Txoj kev piav qhia:Cov txheej txheem kev tsim khoom kub qis qis yog qhov zoo ib yam li autoclave prepreg, qhov sib txawv yog tias cov tshuaj lom neeg ntawm cov resin tso cai rau nws kho tau ntawm 60-120 ° C.

Rau qhov kub qis 60 ° C kho, lub sijhawm ua haujlwm ntawm cov khoom siv tsuas yog ib lub lis piam;rau cov catalysts kub (> 80 ° C), lub sijhawm ua haujlwm tuaj yeem ncav cuag ob peb lub hlis.Lub fluidity ntawm cov resin system tso cai rau kho siv tsuas yog lub hnab nqus tsev vacuum, tsis txhob siv autoclaves.

xaiv cov khoom siv:

Resin: Feem ntau tsuas yog epoxy resin

Fiber: tsis muaj qhov yuav tsum tau ua, ib yam li cov tshuaj prepreg

Cov khoom siv tseem ceeb: tsis muaj qhov yuav tsum tau ua, tab sis kev saib xyuas tshwj xeeb yuav tsum tau them thaum siv cov txheej txheem PVC ua npuas ncauj

Lub ntsiab kom zoo dua:

1) Nws muaj tag nrho cov zoo ntawm cov tsoos autoclave prepreg ((i.))-((vi.))

2) Cov khoom pwm yog pheej yig, xws li ntoo, vim tias qhov kub thiab txias yog tsawg

3) Cov txheej txheem tsim khoom ntawm cov khoom siv loj yog yooj yim, tsuas yog yuav tsum tau nias lub hnab nqus tsev, xa cov cua kub ntawm qhov cub lossis cua kub cua sov ntawm pwm nws tus kheej kom ua tau raws li qhov yuav tsum tau ua.

4) Cov ntaub ntawv ua npuas ncauj tuaj yeem siv tau, thiab cov txheej txheem yog qhov paub tab

5) Piv nrog rau autoclave, lub zog siv qis dua

6) Advanced thev naus laus zis kom ntseeg tau qhov tseeb qhov tseeb thiab rov ua dua

Lub ntsiab tsis zoo:

1) Cov khoom siv tus nqi tseem siab dua li cov fiber ntau qhuav, txawm tias tus nqi resin qis dua aerospace prepreg

2) Cov pwm yuav tsum tiv taus qhov kub siab tshaj qhov txheej txheem infusion (80-140 ° C)

Tej kev siv:Kev ua haujlwm siab cua turbine hniav, cov nkoj loj sib tw thiab yachts, cawm aircraft, tsheb ciav hlau Cheebtsam

10. Non-autoclave txheej txheem ntawm semi-preg SPRINT/beam prepreg SparPreg

Txoj kev piav qhia:Nws yog ib qho nyuaj rau tso tawm cov huab cua npuas ntawm cov khaubncaws sab nraud povtseg los yog overlapping txheej thaum lub sij hawm kho thaum siv prepreg nyob rau hauv thicker lug (> 3 hli).Yuav kom kov yeej qhov teeb meem no, pre-vacuumization tau nkag mus rau hauv txheej txheem txheej, tab sis tseem ceeb heev rau lub sij hawm txheej txheem.

Nyob rau hauv xyoo tsis ntev los no, Gurit tau qhia ib tug series ntawm txhim kho prepreg cov khoom nrog patented technology, ua rau lub chaw tsim khoom ntawm high quality (low porosity) thicker laminates kom tiav nyob rau hauv ib kauj ruam txheej txheem.Lub semi-preg SPRINT yog tsim los ntawm ob txheej ntawm cov fibers qhuav sandwiching ib txheej ntawm resin zaj duab xis sandwich qauv.Tom qab cov khoom tau muab tso rau hauv pwm, lub tshuab nqus tsev twj tso kua mis tuaj yeem tso tawm cov cua hauv nws ua ntej cov resin heats li thiab softens thiab soaks cov fiber.khov kho.

Beam prepreg SparPreg yog ib qho kev txhim kho prepreg uas, thaum kho nyob rau hauv lub tshuab nqus tsev, tuaj yeem yooj yim tshem tawm cov npuas ntawm cov khoom siv ob-ply.

xaiv cov khoom siv:

Resin: feem ntau epoxy resin, lwm cov resins kuj muaj

Fiber: tsis xav tau

Cov khoom siv tseem ceeb: feem ntau, tab sis kev saib xyuas tshwj xeeb yuav tsum tau them rau qhov kub siab thaum siv cov txheej txheem PVC ua npuas ncauj

Lub ntsiab kom zoo dua:

1) Rau cov khoom tuab (100mm), cov khoom siv fiber ntau thiab cov porosity tsawg tseem tuaj yeem tau txais qhov tseeb

2) Thawj lub xeev ntawm cov resin system yog khoom, thiab kev ua tau zoo heev tom qab kub curing

3) Tso cai rau kev siv cov ntaub ntawv uas tsis tshua muaj nqi siab-qhov hnyav fiber ntau (xws li 1600 g / m2), ua rau kom nrawm nrawm, thiab txuag cov nqi tsim khoom.

4) Cov txheej txheem yog siab heev, kev khiav hauj lwm yog yooj yim thiab cov ntsiab lus resin yog precisely tswj

Lub ntsiab tsis zoo:

1) Cov khoom siv tus nqi tseem siab dua li cov fiber ntau qhuav, txawm tias tus nqi resin qis dua aerospace prepreg

2) Cov pwm yuav tsum tiv taus qhov kub siab tshaj qhov txheej txheem infusion (80-140 ° C)

Tej kev siv:kev ua haujlwm siab cua turbine hniav, cov nkoj loj sib tw thiab yachts, cawm lub dav hlau

Post lub sij hawm: Dec-13-2022